Industrial air doors are robust, versatile solutions for harsh environments, offering superior corrosion resistance and durability. They protect against extreme temps, humidity, & chemicals, facilitating seamless flow while maintaining environmental control in manufacturing, warehousing, & cold storage. With advanced sealing mechanisms & durable construction, these doors ensure minimal energy loss, noise reduction, & long-lasting performance, making them ideal for heavy-duty applications. Regular maintenance, including inspections, lubrication, cleaning, & component replacement, is crucial for optimal efficiency & extended lifespan in demanding industrial settings.

In harsh environments, corrosion can be a relentless force, damaging equipment and infrastructure. To combat this, understanding and implementing robust solutions is essential. This article explores the critical role of industrial air doors in mitigating corrosion-related challenges. We delve into the science behind corrosion in demanding settings, highlighting how specialized industrial air doors offer unparalleled protection. Discover key features ensuring longevity, explore diverse application areas, and gain insights into maintenance strategies to maximize their lifespan.

- Understanding Corrosion in Harsh Environments

- The Role of Industrial Air Doors

- Key Features of Corrosion-Resistant Doors

- Application Areas and Benefits

- Maintenance and Longevity Considerations

Understanding Corrosion in Harsh Environments

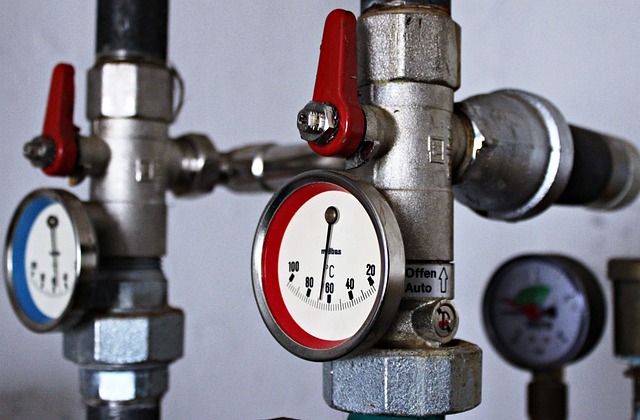

Corrosion is a significant concern in harsh industrial environments, where extreme conditions can accelerate metal degradation. In such settings, where moisture, chemicals, and varying temperatures are prevalent, traditional materials may not withstand the rigors of time. This phenomenon, often referred to as industrial corrosion, poses a critical challenge for equipment maintenance and longevity, especially regarding industrial air doors. These doors, designed for various applications like warehouse opening protection, loading dock barriers, and factory entrance solutions, require robust construction to resist corrosion and maintain their functionality over extended periods.

Understanding the specific causes of corrosion in these environments is vital for selecting appropriate heavy-duty air doors or manufacturing door systems. For instance, a cold storage air door must endure constant exposure to low temperatures and possible condensation, whereas a door in a chemical processing plant faces potential harm from corrosive substances. Therefore, when implementing industrial climate separation solutions, such as large opening air curtains, it’s crucial to choose materials that offer superior corrosion resistance for optimal performance and reduced downtime in challenging settings.

The Role of Industrial Air Doors

Industrial air doors play a pivotal role in creating robust and efficient entrance solutions for harsh environments across various industries. These heavy-duty doors are designed to withstand extreme conditions, offering protection against intense temperatures, high humidity, and corrosive substances that can damage traditional door systems. By acting as effective industrial entrance barriers, they ensure the integrity of manufacturing processes, warehouse operations, and factory entrances.

In demanding sectors such as cold storage, loading docks, and manufacturing facilities, where climate separation is paramount, industrial air doors provide unparalleled versatility. Their ability to operate as large opening air curtains enables seamless flow while maintaining environmental control. Moreover, these doors are ideal for protecting vulnerable areas in factories, serving as reliable warehouse opening protection and efficient factory entrance solutions.

Key Features of Corrosion-Resistant Doors

Corrosion-resistant industrial air doors are designed to withstand the toughest conditions, making them an indispensable solution for harsh environments. These doors are built with premium materials and advanced technologies to ensure longevity and durability in various sectors such as manufacturing, warehousing, and cold storage. Key features include robust construction that prevents rust and corrosion, even when exposed to moisture, extreme temperatures, or harsh chemicals.

Additionally, they offer superior sealing capabilities, providing effective climate separation and minimizing energy loss. Heavy-duty air doors are ideal for industrial entrance barriers, warehouse opening protection, and factory entrance solutions. Their versatile designs cater to various applications, including loading dock barriers, cold storage air doors, large opening air curtains, and even industrial HVAC barriers, ensuring optimal performance and reliability in any setting.

Application Areas and Benefits

Maintenance and Longevity Considerations

Regular maintenance is key to ensuring the longevity of industrial air doors in harsh environments. These doors are designed to withstand extreme conditions but require proper care to maintain their performance and extend their service life. A comprehensive maintenance plan includes routine inspections to identify any signs of wear or damage, especially in areas exposed to corrosive elements like moisture, chemicals, or salt.

Proper lubrication of moving parts, regular cleaning to prevent debris buildup, and timely replacement of worn-out components are essential practices. Additionally, considering the specific challenges posed by the environment—such as temperature fluctuations, humidity, or airborne contaminants—can help in tailoring a maintenance strategy for optimal performance. For instance, using heavy-duty air doors in cold storage facilities may require more frequent checks to ensure they function efficiently while preventing cold air leakage. Effective maintenance not only keeps industrial entrance barriers and warehouse opening protection functioning optimally but also reduces downtime and extends the lifespan of these critical manufacturing door systems.

Industrial air doors are an essential solution for harsh environments, offering superior protection against corrosion. By understanding the impact of corrosion and leveraging the key features of these specialized doors, businesses can ensure extended longevity and optimal performance in challenging conditions. With their versatility and benefits across various sectors, corrosion-resistant industrial air doors prove to be a reliable game-changer in navigating hostile landscapes.