Industrial air doors, with their remote control technology, are pivotal in managing access and enhancing operational efficiency across various sectors. They offer temperature regulation, protect equipment from environmental conditions, and streamline processes in manufacturing plants, warehouses, and cold storage areas. These heavy-duty doors provide seamless operation, security, and climate separation, making them essential for modern industrial settings. Successful deployment requires strategic assessment, custom solutions, regular maintenance, fail-safe mechanisms, and advanced monitoring technologies, ultimately revolutionizing access control and operational efficiency.

Remote-controlled industrial air doors are transforming facility access, enhancing safety and efficiency. This cutting-edge technology offers a new level of control over large, heavy doors used in manufacturing, warehousing, and logistics.

In this article, we explore the world of industrial air doors, delving into their crucial role, benefits, and how remote control technology is revolutionizing access management. We’ll also discuss implementation best practices and highlight compelling case studies showcasing real-world success stories involving these game-changing doors.

- Understanding Industrial Air Doors: Their Role and Benefits

- The Rise of Remote Control Technology in Access Management

- Implementation and Maintenance: Ensuring Seamless Operation

- Case Studies: Real-World Applications and Success Stories

Understanding Industrial Air Doors: Their Role and Benefits

Industrial air doors play a pivotal role in managing access points within facilities, offering numerous benefits for various industries. These heavy-duty air doors are designed to control and regulate airflow, providing an effective barrier against harsh environmental conditions. In manufacturing plants, warehouses, and cold storage areas, where temperature regulation is crucial, industrial air doors act as versatile entrance solutions.

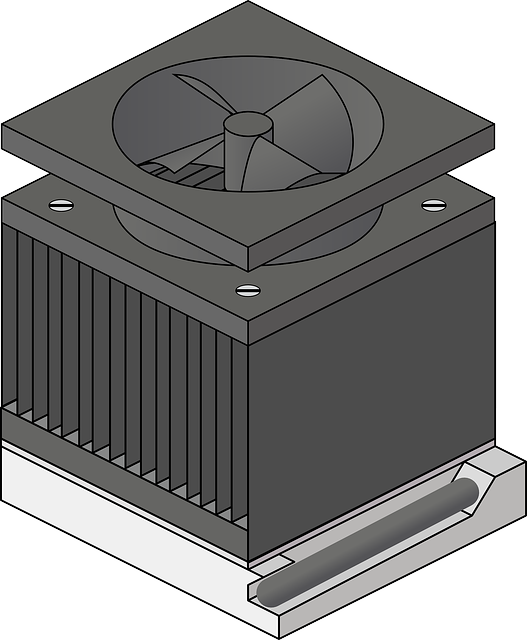

They ensure efficient climate separation, protecting sensitive equipment and goods from external elements. Whether it’s a loading dock or a large opening in a warehouse, these air curtains provide robust protection. Their ability to seal entry points helps maintain the desired internal environment, whether keeping out cold air or containing heated spaces. This is especially valuable for factories with specific HVAC (Heating, Ventilation, and Air Conditioning) requirements, ensuring optimal working conditions and enhancing operational efficiency.

The Rise of Remote Control Technology in Access Management

In recent years, the integration of remote control technology in access management has revolutionized industrial facility operations. This shift is largely driven by the need for enhanced efficiency and safety in environments that utilize heavy duty air doors, manufacturing door systems, and warehouse opening protection. Remote-controlled industrial air doors offer a multitude of benefits over traditional manual operating mechanisms. They provide quick and seamless control, especially in dynamic settings like loading docks, cold storage facilities, and factories, where rapid entrance and exit are crucial for productivity.

The adoption of remote control technology also addresses specific challenges faced by these industries, such as industrial climate separation, large opening air curtains, and the need for robust HVAC barriers. This innovation ensures that access is managed securely without compromising operational speed. With factory entrance solutions now at their fingertips, facility managers can streamline processes, reduce human error, and enhance overall workplace safety, making them indispensable tools in modern industrial settings.

Implementation and Maintenance: Ensuring Seamless Operation

The successful implementation of remote-controlled industrial air doors requires careful planning and consideration of various factors to ensure seamless operation. Facility managers must assess their specific needs, including the size and frequency of access points, environmental conditions, and security requirements. Choosing the right manufacturer that offers custom solutions for heavy-duty air doors is essential, ensuring compatibility with existing infrastructure and meeting unique challenges faced in manufacturing, warehousing, or cold storage environments.

Regular maintenance plays a crucial role in maintaining optimal performance. This includes routine checks to ensure proper sealing, regular cleaning to prevent debris buildup, and timely replacement of worn-out components. For industrial entrance barriers, such as loading dock barriers or warehouse opening protection, remote control systems should be equipped with fail-safe mechanisms and backup power sources to address potential malfunctions. By integrating smart sensors and advanced monitoring technologies, factory entrance solutions can adapt to changing conditions, enhancing safety and efficiency in various manufacturing door systems and climate separation applications.

Case Studies: Real-World Applications and Success Stories

In various industries, remote-controlled industrial air doors have transformed facility access, enhancing safety and operational efficiency. For instance, in manufacturing plants, these doors serve as robust industrial entrance barriers, providing secure entry while facilitating smooth material flow. Case studies in large warehouses show that implementing heavy-duty air doors significantly improves loading dock operations, acting as effective warehouse opening protection. This simple upgrade reduces downtime by eliminating the need for manual door operation, especially in harsh climates.

Furthermore, industrial air doors play a vital role in temperature-controlled environments, including cold storage facilities and industrial HVAC systems. As cold storage air doors, they maintain desired environmental conditions, ensuring product quality. Similarly, large opening air curtains act as versatile factory entrance solutions, offering both climate separation and easy access. These success stories across diverse sectors underscore the versatility and efficiency of remote-controlled industrial air doors in modern facility management.

Industrial air doors, with their versatile applications and enhanced safety features, are transforming facility access management. The integration of remote control technology further simplifies operations, offering increased efficiency and convenience. As demonstrated in various case studies, these innovative solutions have proven to be reliable game-changers for industrial environments, ensuring streamlined access while maintaining optimal security. By embracing the benefits of remote-controlled industrial air doors, businesses can elevate their facility management strategies, creating safer and more accessible workspaces.